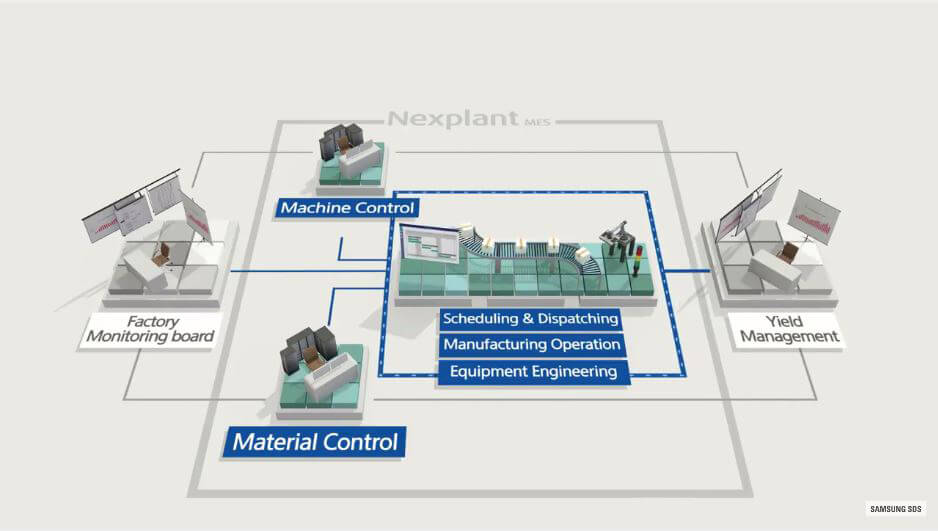

Nexplant MES

Leverage Samsung's manufacturing expertise to respond faster to the market

The Samsung Manufacturing Advantage

Benefits

Rapid market response is possible with optimized manufacturing information management and control solutions

- Full automation 15% Improving productivity

- Set-up time for product model change 50% Reduced

- Standardized interface and control for equipment 40% Reduced TAT (Turn Around Time)

-

Customize your manufacturing for higher efficiency

Get a complete analysis of your manufacturing process, evaluating the production environment using industry standards from the Manufacturing Enterprise Solutions Association.

-

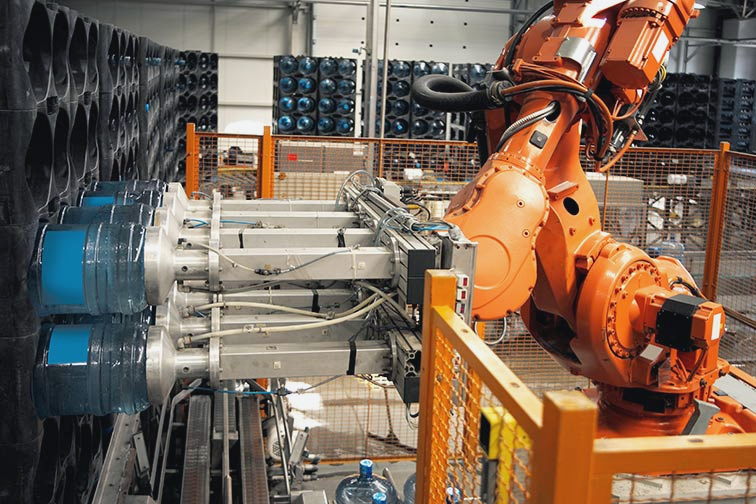

Put our industry-proven experience to work

Keep your facilities running non-stop at just 10ppm. Our expertise is proven in the world’s leading semiconductor foundries and display factories. Upgrade your systems with hot swap without downtime.

-

Boost quality with advanced analytics

Utilize data from real-time monitoring to manage your equipment. Resolve quality issues quickly, achieve better results with high performance parallel processing.

Videos

Let your manufacturing equipment do the work for you. Create your own fully optimized manufacturing process with Nexplant MES to gain the flexibility you need to minimize production time and maximize product quality.

With Nexplant MES SD, enhance your manufacturing competitiveness and achieve the highest level of productivity through continuous diagnosis and monitoring.

Features

-

Schedule & dispatch system

Creates an optimized production schedule for work orders and dispatches to select equipment in real time and achieve the highest level of productivity.

-

Manufacturing operation

Manages resources and processes to meet production standards, while tracking and tracing products to oversee performance and productivity of each production line.

-

Equipment engineering

Collects and processes data from the manufacturing process to enhance product yield and equipment efficiency.

-

Machine control

Automatically collects and standardizes equipment data, automating the production facility with remote equipment control.

-

Materials control

Creates the optimal route for materials to minimize movement time on carriers in fully automated manufacturing facilities.

Case Studies

Global Manufacturing

There is an increasing demand for integrated and flexible management of the Manufacturing Execution System (MES) for global expansion. To accommodate these customer needs, Samsung SDS transitioned the MES to the public cloud for the reliability, processing speed and performance at a similar level as on-premise environments.

Analyst Reports

[Recognition] Samsung SDS is positioned in the Gartner 2021 Magic Quadrant for Industrial IoT Platforms.

* in Magic Quadrant for Industrial IoT Platforms, 2021, Gartner2021

Samsung SDS in a list of the most significant Industrial IoT Software Platform Provider in The Forrester Wave™.

* in The Forrester Wave™: Industrial IoT Software Platforms, Q3 20212021

Samsung SDS Nexplant is considered an important future tool for the smart factory strategy in defining the next-generation paradigm.

* IDG Tech Dossier 2018Use Cases

-

Minimize loss with a flexible and automated MESManufacturers can react to sudden production changes faster and more efficiently, minimizing loss caused by downtime.

Minimize loss with a flexible and automated MESManufacturers can react to sudden production changes faster and more efficiently, minimizing loss caused by downtime. -

Real time facility and equipment managementProduction managers can ensure consistent yield and high quality products by easily keeping track of the facility and equipment in real time.

Real time facility and equipment managementProduction managers can ensure consistent yield and high quality products by easily keeping track of the facility and equipment in real time. -

Seamless production through stronger controlsEnhance productivity and reduce downtime. Our smart control system can automatically maneuver so that the right products go to the right manufacturing lines.

Seamless production through stronger controlsEnhance productivity and reduce downtime. Our smart control system can automatically maneuver so that the right products go to the right manufacturing lines.

Specifications

-

Operating System

IBM, SUN, HP, Linux, Windows (Java 1.6, .NET 4.0)

-

Database

Oracle, SQL-Server, DB2, MySQL

-

Middleware

TIB Rendezvous, Highway 101, various language support

Related Offerings

Find out more about our offerings

Various services will be provided by freely utilizing 3D data from different devices. Users can realize innovation in work environments.

Product design and verification can be completed more swiftly through the auto-implementation of CAE and simulation analytics. As products become more complicated and processes more refined, such requirements can be dealt with through automation/optimization based on data while accelerating the production speed.

The optimized management will be available throughout the entire life cycle of asset from purchaing factory equipment to operation, maintenance and discharging. By linking information real time and accurately analyzing the information, users can secure the predictability of the process and the transparency in the status of asset.

This is the most optimized solution that manages PCs on site in an integrated manner by controlling unauthorized software, blocking security threats, and deploying the central control of work systems.

Whether you’re looking for a specific business solution or just need some questions answered, we’re here to help