Nexplant SLM

E2E Simulation Lifecycle Management Solution designed and driven by Data

Automate CAE based on AI and Cloud for world-class product performance and quality

Benefits

Automate CAE execution by utilizing large amount of semiconductor data

- One & only around the globe Web-based GDS Collaboration Platform *GDS: Standard file format for semiconducctor layout

- Optimized layout viewer for semiconductor 9 times faster speed *GDS Move Rendering speed compared to that of the generally used tools

- Support public cloud services Registered on MS Azure Marketplace

-

Execute CAE automatically and reduce verification time

Automate the execution of tools based on workflows. Reduce the standby time caused by engineers’ repeated work and executing tools. That shortens lead time. Support validated and optimized algorithms, so that customers can have design options optimized for their business.

-

Collaborate with Designers-Manufactures-Customers based on GDS

Previously, semiconductor data (GDS/OASIS, Jobdeck) is limitedly used for security and performance issue. Now, Nextplant SLM builds an environment where the massive data is available for external research networks, including manufacturing divisions (process, measurement) and customers. Speed up the time to validate design and ramp up mass production.

-

Optimize HPC resources to minimize CAE execution’s standby

The demand is rapidly increasing to invest in high-performing computing infra (HPC) for hundreds of CAE tools and AI model training. Nexplant SLM comprehensively monitors HPC cluster operation disparate per workload. Improve HPC operation efficiency with a real-time Job analysis and minimize the time for simulation standby.

Features

-

Real-time check for design-verification progress with automatic log collection

Apply CAE Log Scanner and Parser in a tool based. Configure a meaningful verification DB from the large-volume and asynchronous logs. Dashboard shows a real-time progress of design-verification founded on the configured verification DB.

-

Streaming-based GDS visualization

GDS(Graphic Data System) DB and web architecture support a simultaneous visualization for multiple users, not an individual loading of massive data. Integrate with master data, measurement-request info and other data easily.

-

Integrated workplace from engineer design to verification

Integrate the environment where complicated settings and execution of hundreds of CAE tools, HPC infra and CAE resources licensing and other high-priced CAE resource management, manual collection and analytics of data verification are scattered individually. Integrate such environment into a GUI-based one holistically for design-verification.

-

Scalable open source architecture

Support the optimal performance and stability with the latest framework-centered architecture, easily scalable open source architecture ranging from a single project up to large-scale development offices.

Use Cases

-

Automate ASIC design tool chain and verification dashboardConnect silo works and shorten verification time from 90 to 60 days with automated collaboration workflow. Validate many CAE tools' progress in real time and create verification report automatically.

Automate ASIC design tool chain and verification dashboardConnect silo works and shorten verification time from 90 to 60 days with automated collaboration workflow. Validate many CAE tools' progress in real time and create verification report automatically. -

Reduce defect rate by optimizing configuration designMinimize deformation rate of products with injection molding. Improve performance by adopting platforms with design optimized algorithms. (20% higher performance as for A/C’s blades and etc.)

Reduce defect rate by optimizing configuration designMinimize deformation rate of products with injection molding. Improve performance by adopting platforms with design optimized algorithms. (20% higher performance as for A/C’s blades and etc.) -

Automatically create measurement instructions and recipes with GDSAutomate inspection/measurement based on GDS (Graphic Data System) streaming viewer. Reduce lead time and experience a shutdown-zero operation.

Automatically create measurement instructions and recipes with GDSAutomate inspection/measurement based on GDS (Graphic Data System) streaming viewer. Reduce lead time and experience a shutdown-zero operation. -

Forecast CAE-resource demand via real time analyticsMonitor your HPC cluster, individually operated according to CAE job elements. Maximize the use of resources supported by ensuring the foothold for dynamic cluster provisioning.

Forecast CAE-resource demand via real time analyticsMonitor your HPC cluster, individually operated according to CAE job elements. Maximize the use of resources supported by ensuring the foothold for dynamic cluster provisioning.

Related Offerings

Find out more about our offerings

Various services will be provided by freely utilizing 3D data from different devices. Users can realize innovation in work environments.

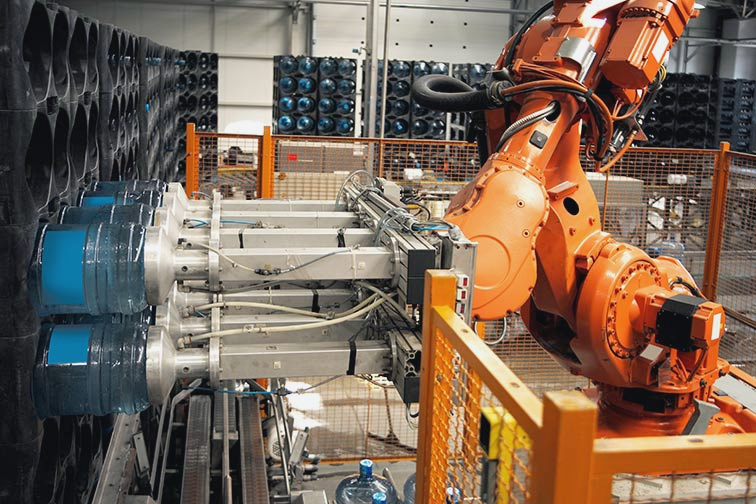

The optimized management will be available throughout the entire life cycle of asset from purchaing factory equipment to operation, maintenance and discharging. By linking information real time and accurately analyzing the information, users can secure the predictability of the process and the transparency in the status of asset.

This is the most optimized solution that manages PCs on site in an integrated manner by controlling unauthorized software, blocking security threats, and deploying the central control of work systems.

Whether you’re looking for a specific business solution or just need some questions answered, we’re here to help