MES

Comprehensive MES solutions and services including provision, implementation, and operation, tailored for semiconductor, LCD, parts & materials, and lithium ion battery industries.

Maximize cost efficiency, quality, and production competitiveness with proven manufacturing solution from Samsung.

We optimized manufacturing processes to reduce lead times while enhancing productivity and quality.

We also delivered real-time integrated operational platforms to maximize manufacturing competitiveness across multiple manufacturing sites.

Key Benefits

We implement system-driven fully automated manufacturing to enhance manufacturing productivity and optimize operation.

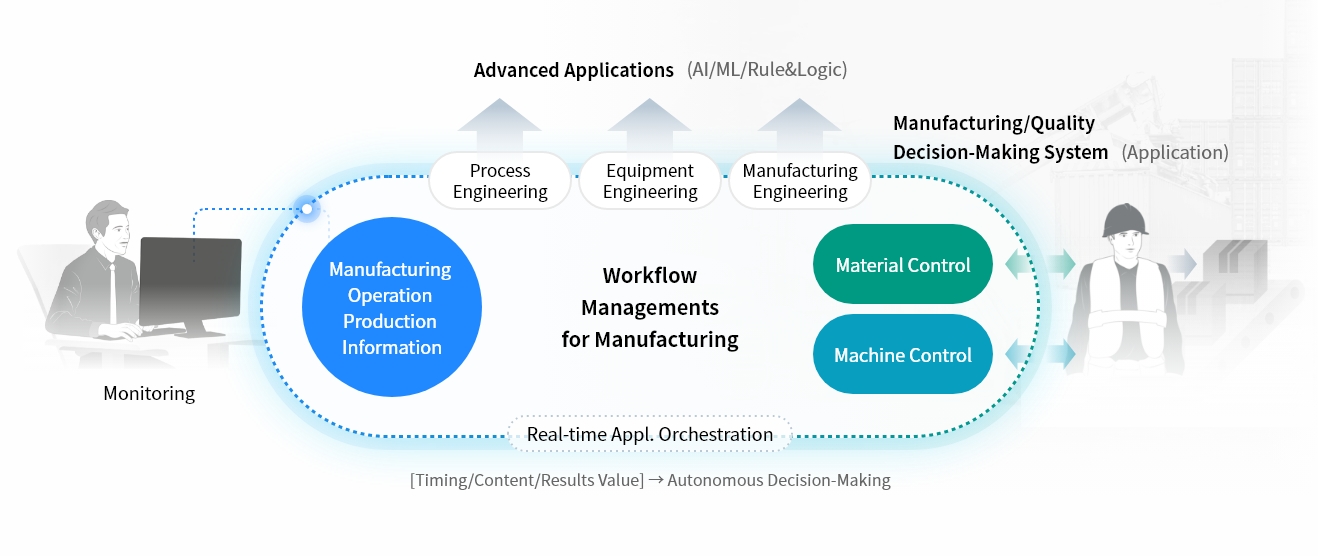

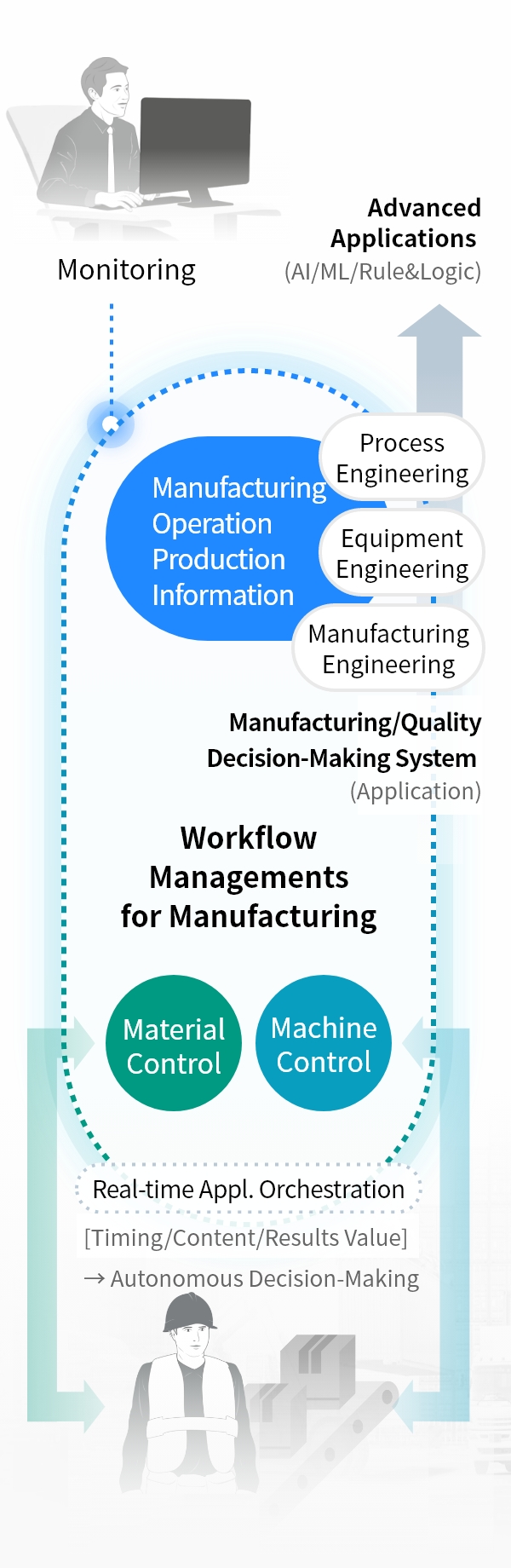

Advanced Applications (AI/ML/Rule & Logic)

Workflow Managements for Manufacturing

Manufacturing/Quality Decision-Making System (Application)

- Process Engineering

- Equipment Engineering

- Manufacturing Engineering

Advanced Applications (AI/ML/Rule & Logic)

Manufacturing Operation Production Information

Material Control Machine ControlWorkflow Managements for Manufacturing monitoring

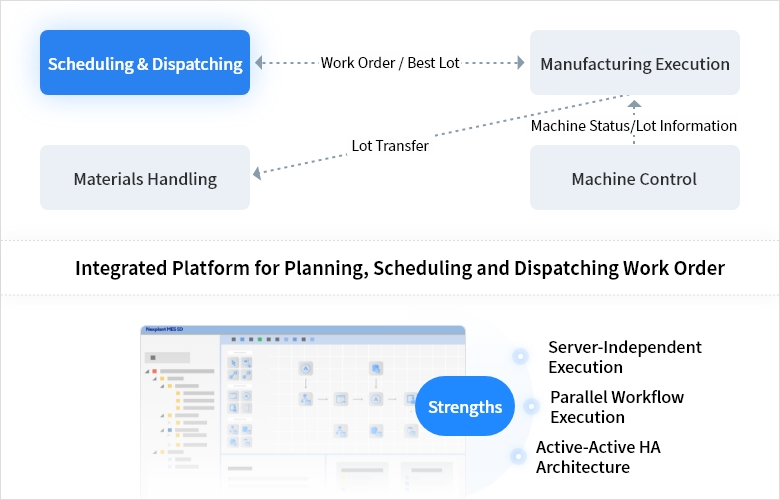

Scheduling & Dispatching

Nexplant MES Scheduling and Dispatching

An integrated tool for developing and operating systems for production management(forecasting, scheduling) and logistics automation(real-time dispatching).

Integrated Platform for Planning, Scheduling and Dispatching Work Order

Strengths: Server-Independent Execution,Parallel Workflow Execution,Active-Active HA Architecture

-

Production Planning and Scheduling

- Production Target by Process

- Optimal Production Sequencing of Processes and Machines

-

Real-time Dispatching

- Machine Dispatching Based on Job Priority-ranking

- Machine Event-driven Job Dispatching

-

Capacity Simulation

- Manufacturing Capacity Planning

- Static Simulation

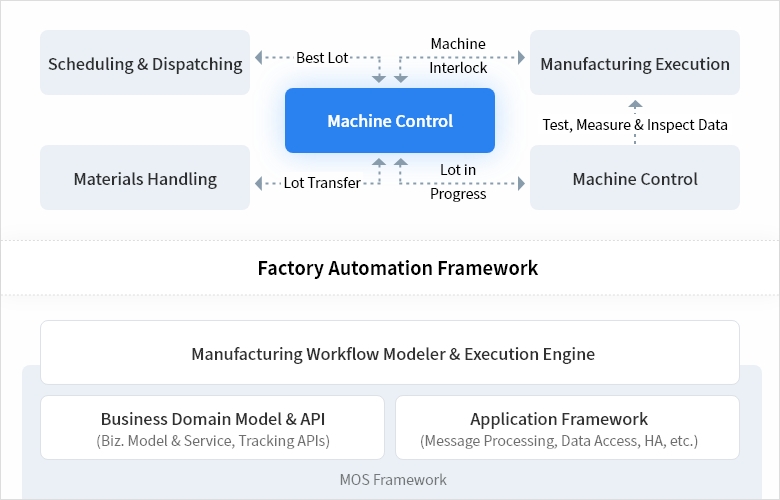

Manufacturing Execution

Nexplant MES Manufacturing Operation

An integrated manufacturing solution to automate production and efficiently manage resource with real-time data collection.

Factory Automation Framework

MOS Framework

Manufacturing Workflow Modeler & Execution Engine

Biz Domain Model & API(Biz Model & Service, Tracking APIs)

Application Framework (Message Processing, Data Access, HA, etc.)

-

Resource Management : Machine, Personnel, Tools, Molds Management

-

Data Collection : Real-time Data Collection

-

WIP Management : Inventory, Progress

-

Tracking : Real-Time Production Tracking & Traceability

-

Quality Control : Inspection, Defect Management & Tracking

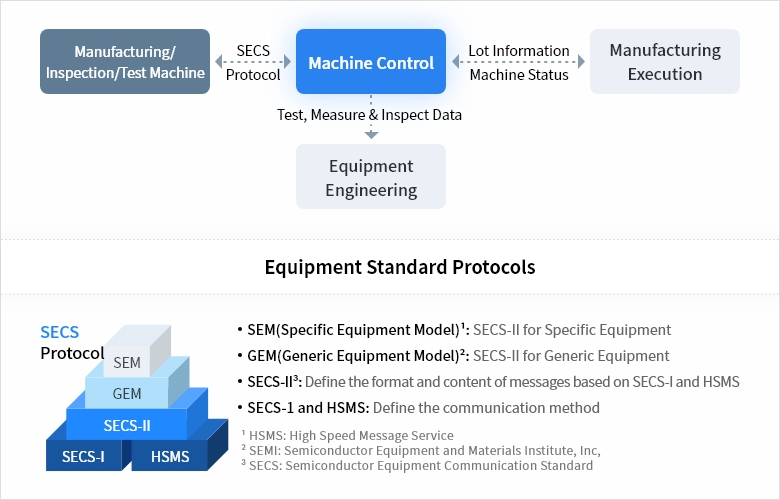

Machine Control

Nexplant TC (Tool Control)

A standard protocol-based equipment remote control solution that interfaces equipment data collection with engineering systems for factory automation.

Equipment Standard Protocols

SECS Protocol

- SSEM(Specific Equipment Model)¹: SECS-II for Specific Equipment

- GEM(Generic Equipment Model)²: SECS-II for Generic Equipment

- SECS-II³: Define the format and content of messages based on SECS-I and HSMS

- SECS-I and HSMS: Define the communication method

-

Automated SEMI-Compliant Equipment Data Collection/Management/Control

-

Visual Workflow Modeling Tool for Defining Business Rules and Equipment Communication Rules

-

Real-Time Monitoring and Automatic Failover for Zero Downtime Operation

FAQ

Find answers to frequently asked questions.

-

A. Click "License" at the bottom of our website for the license policy for each solution. (https://www.samsungsds.com/en/etc/license/index.html)

For detailed quotes, please contact us at the email addresses below.

mos.techsupport@samsung.com , sd.techsupport@samsung.com, tc.techsupport@samsung.com -

A. Technical support is available upon signing a maintenance contract after the warranty expires.

If you require technical support during use, please contact us at mos.techsupport@samsung.com for assistance with your inquiries.

Minor upgrades are provided free of charge, while major upgrades may require an additional fee and further consultation.

Without a maintenance contract, minor upgrades will not be supported.

For detailed support plans, please contact us at the email addresses below.

mos.techsupport@samsung.com , sd.techsupport@samsung.com, tc.techsupport@samsung.com

-

A. Our solution is developed based on machine message interfaces in highly automated high-tech industries. We kindly ask for your understanding as we are unable to provide a test environment.

-

A. The solution can be integrated with your enterprise system using DB to DB interface. To inquire about integration services, please contact us at the email addresses below.

mos.techsupport@samsung.com , sd.techsupport@samsung.com, tc.techsupport@samsung.com -

A. We offer solution training sessions for customers with maintenance contracts. If you would like to attend a training session, please contact us at the following email addresses below.

mos.techsupport@samsung.com , sd.techsupport@samsung.com, tc.techsupport@samsung.com

Related Offerings

Integrated and optimized solutions and services for materials handling system, from consulting to transport control and optimal operations.

Optimize factory and warehouse operations with Samsung SDS materials handling automation solutions.

Whether you’re looking for a specific business solution or just need some questions answered, we’re here to help