Domestic Electronics Component Manufacturer

Establishment of Enterprise Asset Management

""The company’s competitiveness in facility management has been strengthened by establishing the next-generation facility management system with the integrated management for all scattered workplaces worldwide through various measures including: systematic management based on standard processes and quality improvement and cost reduction in facility preservation by sharing each workplace’s facility operation know-how.” "

Domestic Electronics Component ManufacturerChallenge

Company A, a domestic electronics component manufacturer, had difficulties in facility set up and operation due to more of physically scattered workplaces. In addition, there are growing needs of the introduction of new technologies including the mobile utilization level for the predictive maintenance system and site with facility preservation.

Also, the existing system had some issues of function allocation, user convenience and performance issues, which drastically deteriorates development productivity and operation efficiency. There are also other needs of system connectivity by analyzing environment safety and accidents.

Solution

Based on Nexplant EAM, Company A, a domestic electronics component manufacturer, the company has reflected major voices of customers into a new global facility management system.

ㆍStandard information system: Manage the necessary information by standardizing including composition, location, disorder codes, items for inspection, work standards and standards for preventive maintenance

ㆍ Equipment: provide auto-issuance of order placement according to Time Based Maintenance (TBM) & Condition Based Maintenance (CBM)

ㆍ Component SCM: Provide functions to manage purchase, order placement, warehousing and safe volume of inventory in terms of backup, manage auto-placement of orders, repair devices on site, repair device by outsourcing partners and function as a repair center.

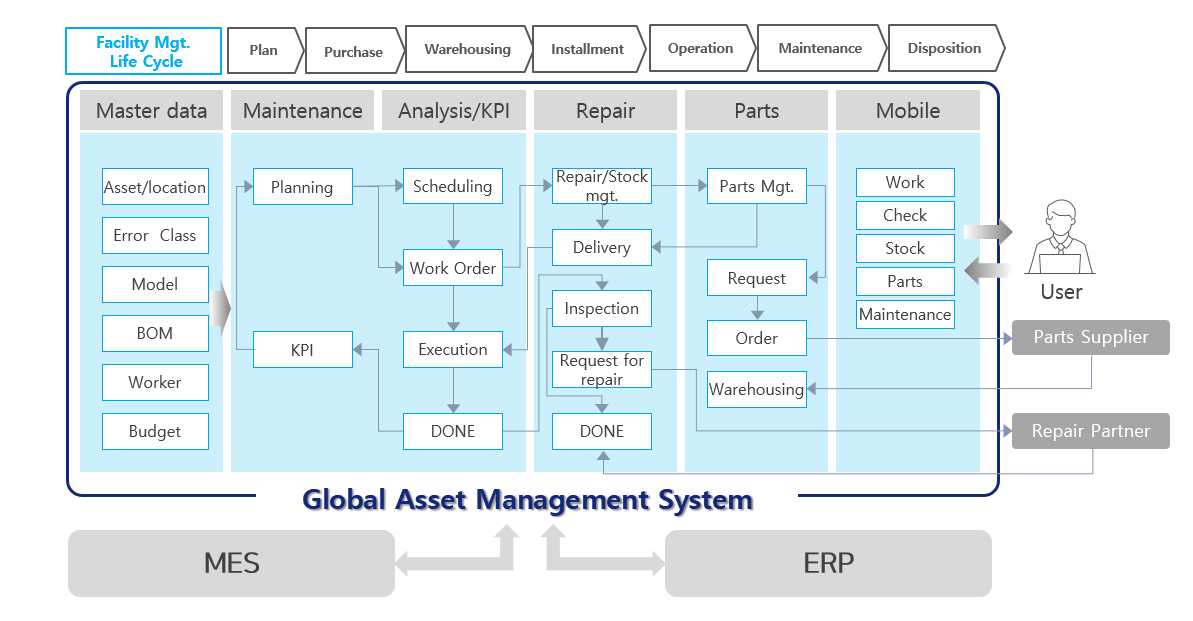

Facility Mgt. Life Cycle → Plan → Purchase → Warehousing → Installment → Operation → Maintenance → Disposition

Global Asset Management System ↔ User- Master data

- Asset/location

- Error Class

- Model

- BOM

- Worker

- Budget

Master data → Maintenance

- Maintenance

- Planning → Scheduling, Work Order

- KPI → Planning

- Analysis/KPI

- Scheduling → Work Order → Execution → DONE(Analysis/KPI) → KPI, Inspection

- Work Order → Repair/Stock mgt.

- Repair

- Repair/Stock mgt. → Parts Mgt.

- Repair/Stock mgt. → Delivery → Execution

- Inspection → Request for repair → Repair Partner → DONE(Repair)

- Inspection → DONE(Repair)

- Parts

- Parts Mgt. → Delivery → Execution

- Parts Mgt. → Request → Order → Parts Supplier → Warehousing

- Mobile

- Work

- Check

- Stock

- parts

- Maintenance

Global Asset Management System ↔ MES

Global Asset Management System ↔ ERP

Benefit

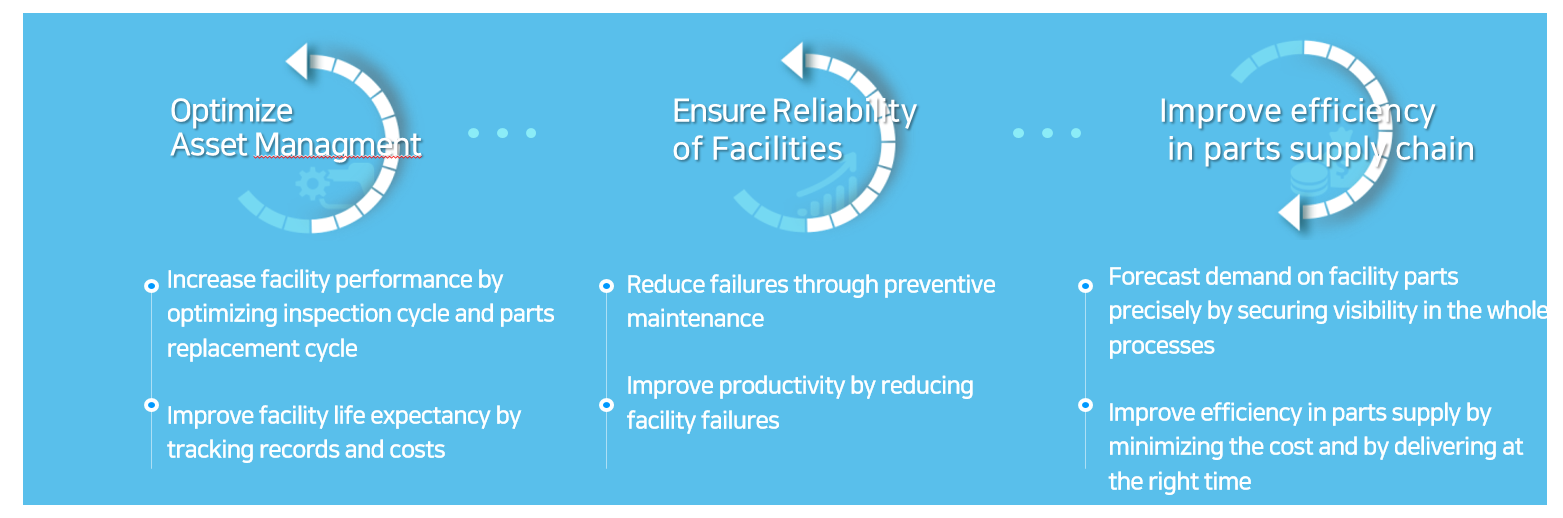

Company A, a domestic electronics component manufacturer, has experienced the following benefits by establishing the next generation’s facility management system.

ㆍ Improve facility performance by optimizing the life cycle management for facilities and components

ㆍ Secure reliability through preventive maintenance and improve productivity by reducing malfunctioning and disorder

ㆍ Reduce inventory and purchase cost by securing visibility of facility components and efficiency in component supply

- Optimize Asset Managment

- Increase facility performance by optimizing inspection cycle and parts replacement cycle

- Improve facility life expectancy by tracking records and costs

- Ensure Reliability of Facilities

- Reduce failures through preventive maintenance

- Improve productivity by reducing facility failures

- Improve efficiency in parts supply chain

- Forecast demand on facility parts precisely by securing visibility in the whole processes

- Improve efficiency in parts sypply by minimizing the cost and by delivering at the right time