Công Ty Lắp Ráp Điện Tử trong nước

Thành lập Nền tảng Phân tích Chất lượng trong Sản xuất Lắp ráp

""The company was able to provide the integrated management for quality including development of faulty cause factors, pre-sensing for quality issues and control of roll-out quality. This was possible by securing a smart quality innovation system that runs from components to manufacturing, shipping and arrival at the market. " "

Công Ty Lắp Ráp Điện Tử trong nướcChallenge

Company A, a domestic electronic assembly company, was implementing quality management activities that focus on core areas in order to improve the quality system. The company has suffered from enormous damage cost

and issues directly related to deteriorated reliability of the company when there is some faulty from the products that are rolled out in the market.

Under this quality management system, it has been difficult to secure preemptive responsive capability to accident-causing faulty and establish a system to clarify the mechanism for chronic faulty. Also, the company had trouble with the shipping gate control for light faulty.

Therefore, in the assembly manufacturing, it has become important to pursue the integrated quality tracking system for the process of components, manufacturing and arrival at the market and establish a standardized management system based on the quality analysis platform in order to secure a smart quality innovation system in assembly manufacturing.

Solution

Company A, a domestic electronic assembly company, has secured data regarding quality of process of components, manufacturing, shipping and arrival to the market in order to establish a smart quality management system.

By utilizing Brightics AI, the company has established a quality analysis platform for the entire company.

The company was able to establish a data warehouse that links manufacturing data and quality data in the course of component-process-shipping-arrival to the market.

The detailed cause analysis has been established regarding pre-control of component quality and breakaway items from processes.

The solution enables users to control the strictness of shipping inspection based on analysis results.

The 24/7 monitoring covers the trend of faulty in the market, which helps realize an auto-analysis/reporting system regarding faulty causes in the market.

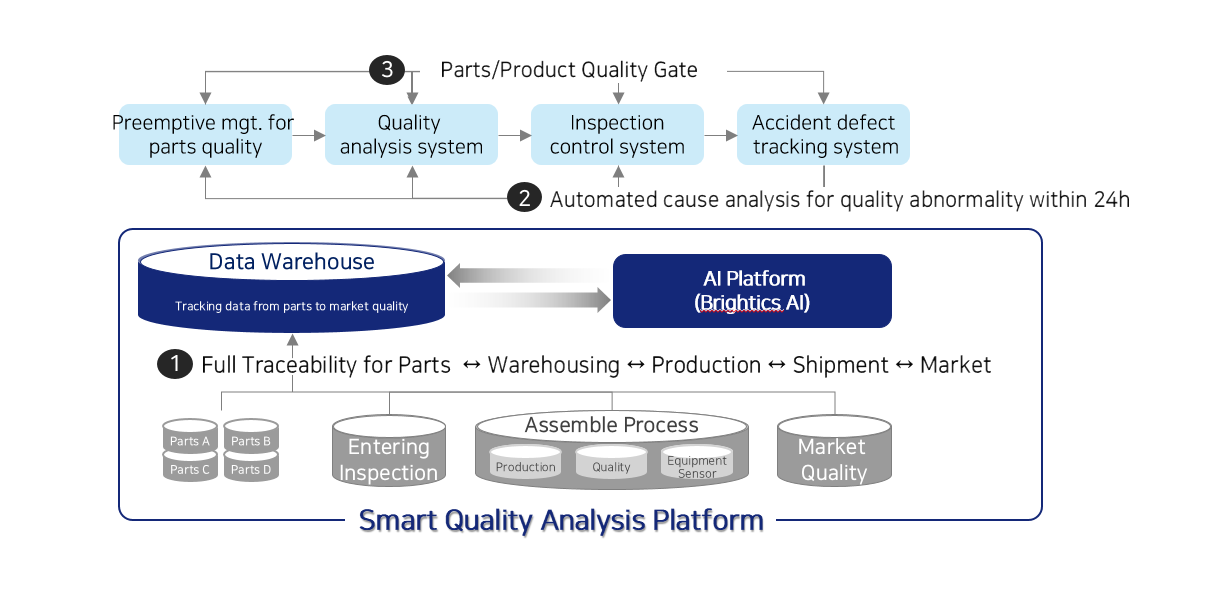

- 1. Full Traceability for Parts ↔ Warehousing ↔ Production ↔ Shipment ↔ Market

- Parts A,B,C,D - Entering inspection - Assenble Process(Production, Quality, Equipment Sensor) - Market Quality

- Data Warehouse (TrackingData from parts to market quality) ↔ AI Platform (Brightics AI)

- 2. Automated cause analysis for quality abnormailty whithin 24h

- Preemptive mgt.for Parts quality → Qualityanalysis system → inspection control system → Accident defect tracking system

- 3. Parts/Product Quality Gate

- Preemptive mgt.for Parts quality → Qualityanalysis system → inspection control system → Accident defect tracking system

Benefit

Company A, a domestic electronic assembly company, has established the solid system and process for quality innovation.

Quantitative benefits

- Reduce quality cost by preemptively respond to accident-causing faulty and strengthen the shipping control for aging faulty

- Analyze mechanism regarding how data-based faulty occurs

Qualitative benefits

- Realize the data governance by establishing a data warehouse for quality throughout the entire company

- Enhance work efficiency through 1st cause analysis on market products with faulty and auto-reporting