Global Electronics Manufacturer

Integrated energy management system based on data analytics

"“Since real-time monitoring for energy consumption status is possible, we can easily find out waste factors of every production process & facility and promptly response.""

Energy management Part Leader, Global Electronics ManufacturerChallenge

This electronics manufacturer pays USD 135 million for year as an energy expense. Also, energy efficiency was an important task to secure competitiveness in manufacturing as their energy cost kept increasing.

The partner thought it is essential to do the activities to analyze the energy consumption status and energy efficiency by process and facility.

However, the partner is producing various products and has a variety of facilities in a large workplace.

That disables the partner to respond to the challenges with limited on-site activities by relevant workforce.

To that end, there was a need for the system to analyze the energy consumption status and energy efficiency real time.

The partner also wanted to conduct sustainable activities for energy reduction by analyzing causes of efficiency change and establishing an immediate response system.

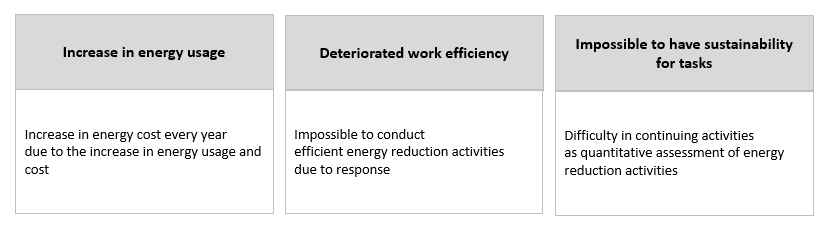

- Increase in energy usage

- Increase in energy cost every year due to the increase in energy usage and cost

- Deteriorated work efficiency

- Impossible to conduct efficient energy reduction activities due to response focusing on site

- Impossible to have sustainability for tasks

- Difficulty in continuing activities as quantitative assessment of energy reductionactivities is impossible

Transformation

Energy-related data integration and integrated energy management system for the entire company have been implemented.

[Energy monitoring]

ㆍ Automatically gather for energy usage & operation data, enhance data integrity

ㆍ Visualize real-time energy usage by process and facility

ㆍ Visualize energy intensity by business division, factory and product

[Analyze energy efficiency & cause of fluctuation]

ㆍ Develop models to analyze facilities that consume a lot of excessive energy

ㆍ Draw efficiency variables and optimal values

[Establish management systems for energy estimation]

ㆍ Predict energy consumption based on energy usage data analytics

ㆍ Establish energy reduction plan & activities based on forecast value

Service

SDS Energy Service

Samsung SDS provides services from energy consulting to total services regarding infrastructure and system development depending on business type.

■ Energy consulting: energy diagnosis and analysis of consumption patterns, establishment of optimization measures

■ Measuring infrastructure establishment: establishment infrastructure as well as measures for IoT-based infrastructure to effectively manage energy

■ Integrated data management : Data gathering, cleansing and saving from various IoT equipment/systems

■ Data analysis: Data modeling and predictive simulation for AI-based efficiency analysis

■ Integrated management system implementation: development of control systems for energy plan/performance management, energy efficiency analysis and optimal operation

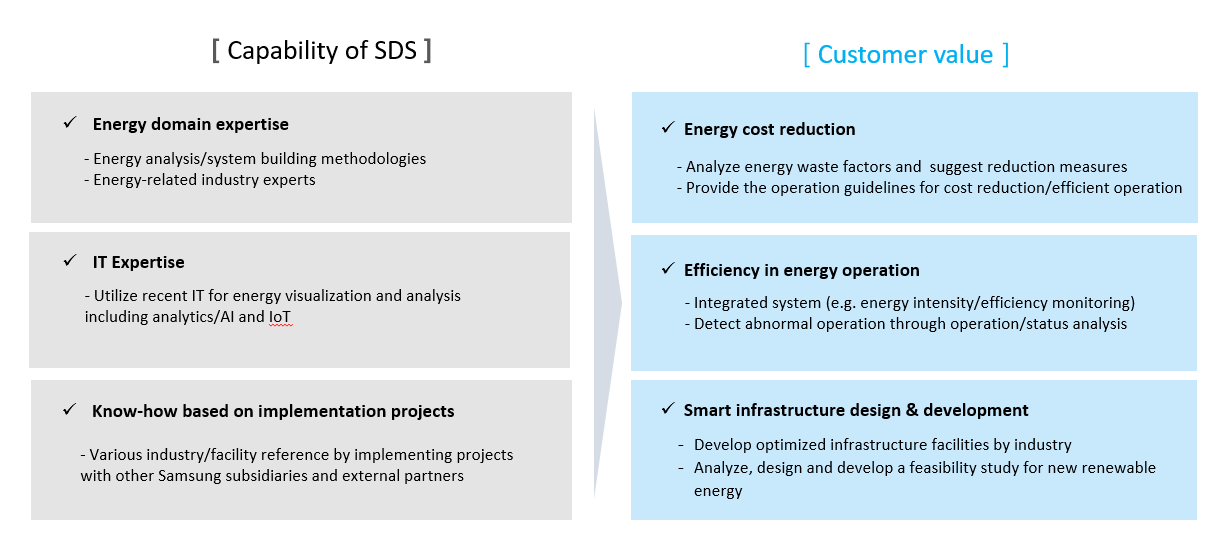

- Capability of SDS

-

Energy domain expertise

- Energy analysis/system building methodologies

- Energy-related Industry experts

-

IT Expertise

- Utilize recent IT for energy visualization and analysis including analytics/AI and IOT

-

Know-how based on implementation projects

- Various industry/facility reference by implementing projects with other Samsung subsidiaries and external partners

- Customer value

-

Energy cost reduction

- Analyze energy waste factors and suggest reduction measures

- Provide the operation guidelines for cost reduction/efficient operation

-

Efficiency in energy operation

- Intergrated system (e.g. energy intensity/efficiency monitoring)

- Detect abnormal operation through operation/status analysis

-

Smart infrastructure design & development

- Deveop optimized infrastructure facilities by industry

- Analyze, design and develop a feasibility study for new renewable energy

Benefit

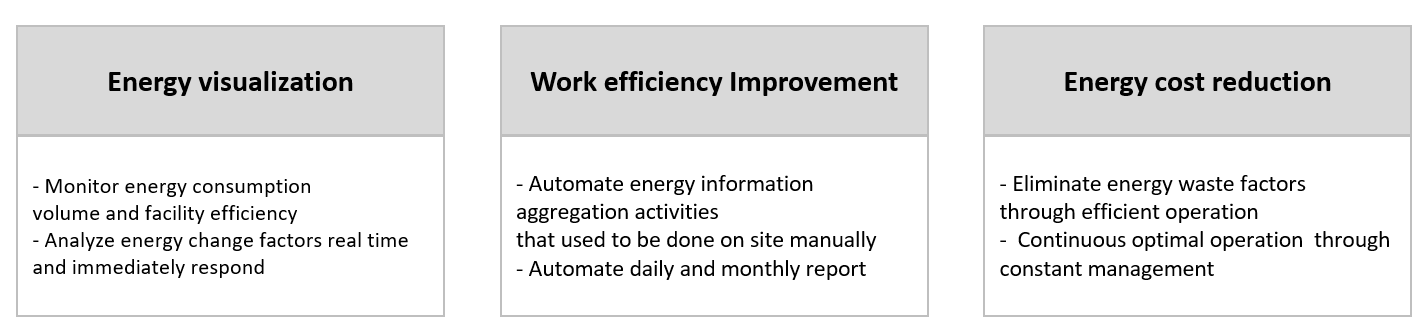

Partners have secured the ground for energy reduction through energy visualization at workplaces,

which enables them to have reasonable operation of the facilities and systems.

- Energy visualization

- - Monitor energy consumption volume and facility efficiency

- - Analyze energy change factors real time and immediately respond

- Work efficiency Improvement

- - Automate energy information aggregation activities that used to be done on site manually

- - Automate daily and monthly report

- Energy cost reduction

- - Eliminate energy waste factors through efficient operation

- - Continuous optimal operation through constant management