Are you spending too much time checking product orders?

At manufacturing companies, it is easy to become trapped in a never-ending cycle of repetitive tasks from checking the order status of a diverse range of products, gathering each factory’s production, etc.

Now, let Brity RPA take care of simple tasks such as identifying order and production status and gathering defect rates!

Brity RPA (Robot Process Automation) reduces work inefficiency and human errors in tasks such as downloading, manually organizing, and creating daily reports, allowing you to focus on developing product ideas.

Save me! Brity RPA - Manufacturing Sector

Ms. Deer: Hello. I'm Ms. Deer working at an apparel company.

Narration: Welcome to the era of data-driven manufacturing and retail.

Ms. Deer: It's a perfect fit!

(Looking at the clothes she is wearing) Customized collar, customized sleeve length, handpicked materials and colors

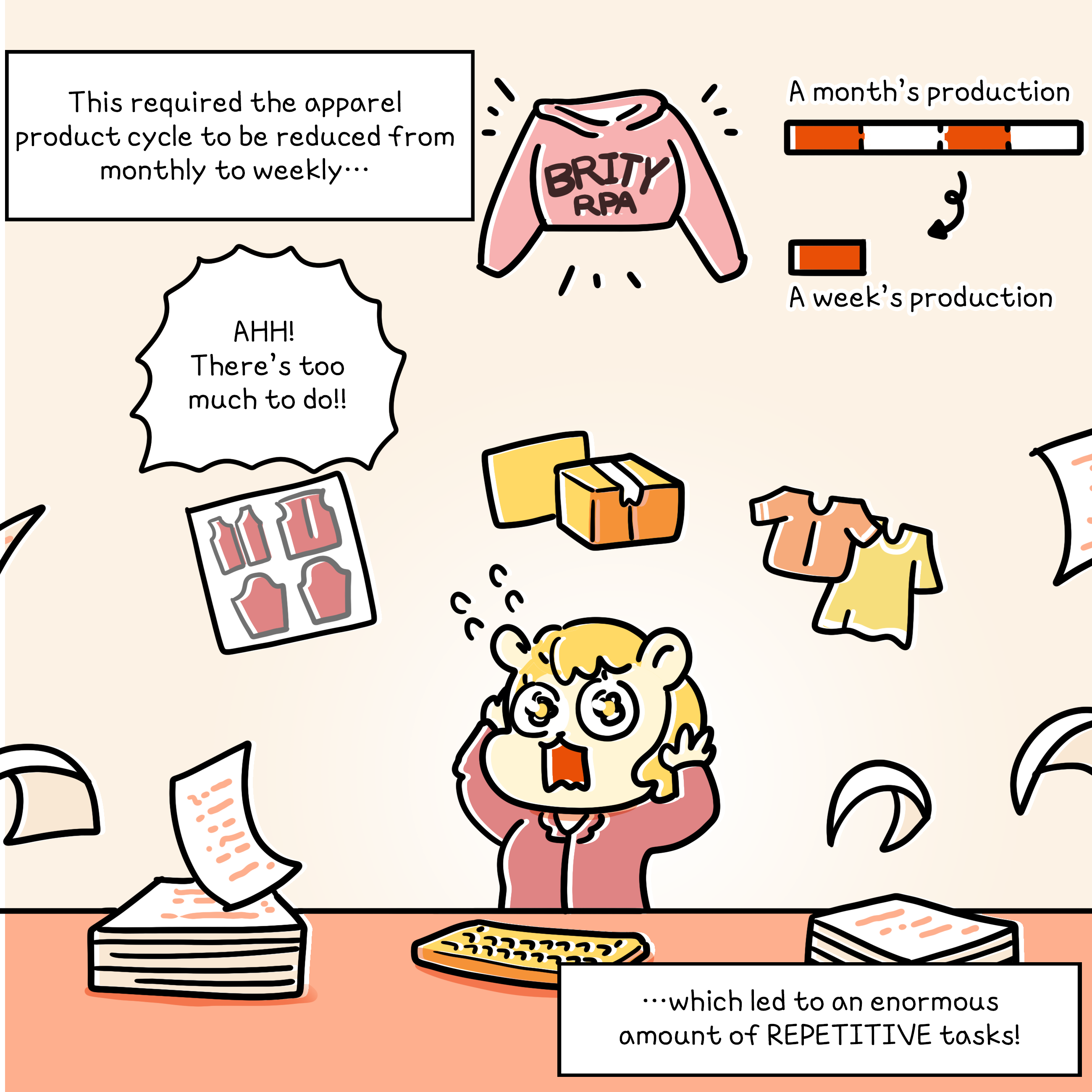

Narration: The trend is changing from mass production to quickly providing customized clothes that satisfy individual preferences.

Narration: This required the apparel product cycle to be reduced from monthly to weekly...which led to an enormous amount of REPETITIVE tasks!

Product cycle) BRITY RPA: A month's production to a week's production

Ms. Deer: AHH! There's too much to do!!

Narration: First, I must verify the product order status. A more diverse product line makes checking products even trickier.

A Buyer: 100 Green Patterned Shorts

B Buyer: 150 Cotton Long Tiered Skirts

C Buyer: 200 Additional Over sized Puffer Jackets!

Ms. Deer: I'm so busy, so busy!!

Narration: Then I have to check the production status of factories around the world every day. Without any standardized format, each factory's product data has to be reformatted one form at a time.

Production status of factories: 100,000 in Vietnam, 220,000 in China, 160,000 in India, 120,000 in Myanmar

Ms. Deer: AHHH! Why are there so many kinds of products!

Narration: There's more...product defect data must be organized separately!

Message alarm: Ding! Ding!

Vietnam factory message: 3 L Green Chino Shorts Defective, 24 S Nylon Shorts Defective

Message alarm: Ding! Ding!

Myanmar factory message: 3 XL Dry Polo Shirts Defective, 4 XS Cotton Graphic-T Defective

Ms. Deer: Will this ever end?!?!

Ms. Deer: I can't spend this much time on repetitive tasks every day! There is only one way out of this...Help me! Brity RPA!!!!

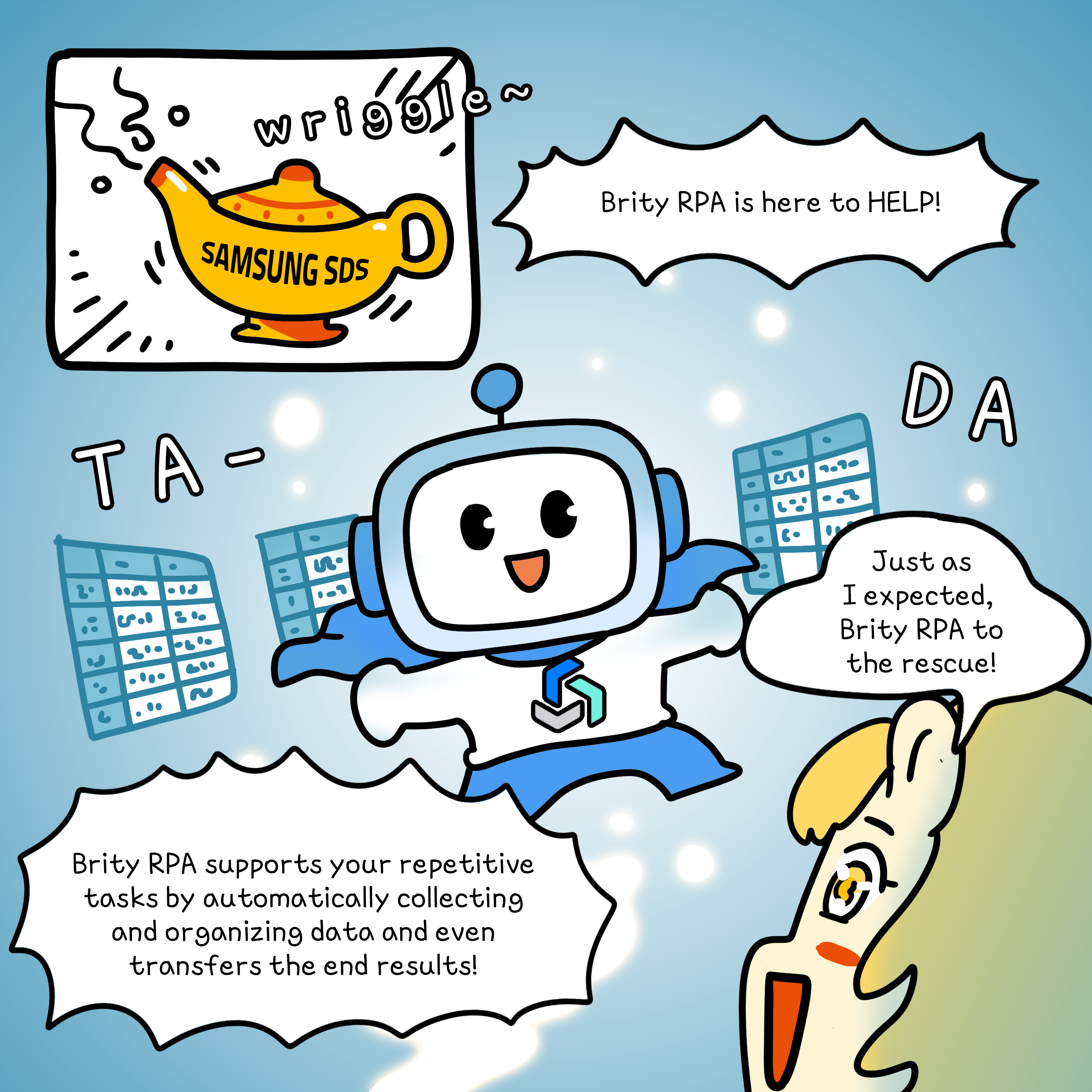

Aladdin lamp(Samsung SDS): Wriggle

Aladdin lamp(Samsung SDS): Wriggle

Brity bot (TA-DA) Brity RPA is here to HELP! Brity RPA supports your repetitive tasks by automatically collecting and organizing data and even transfers the end results!

Ms. Deer: Just as I expected, Brity RPA to the rescue!

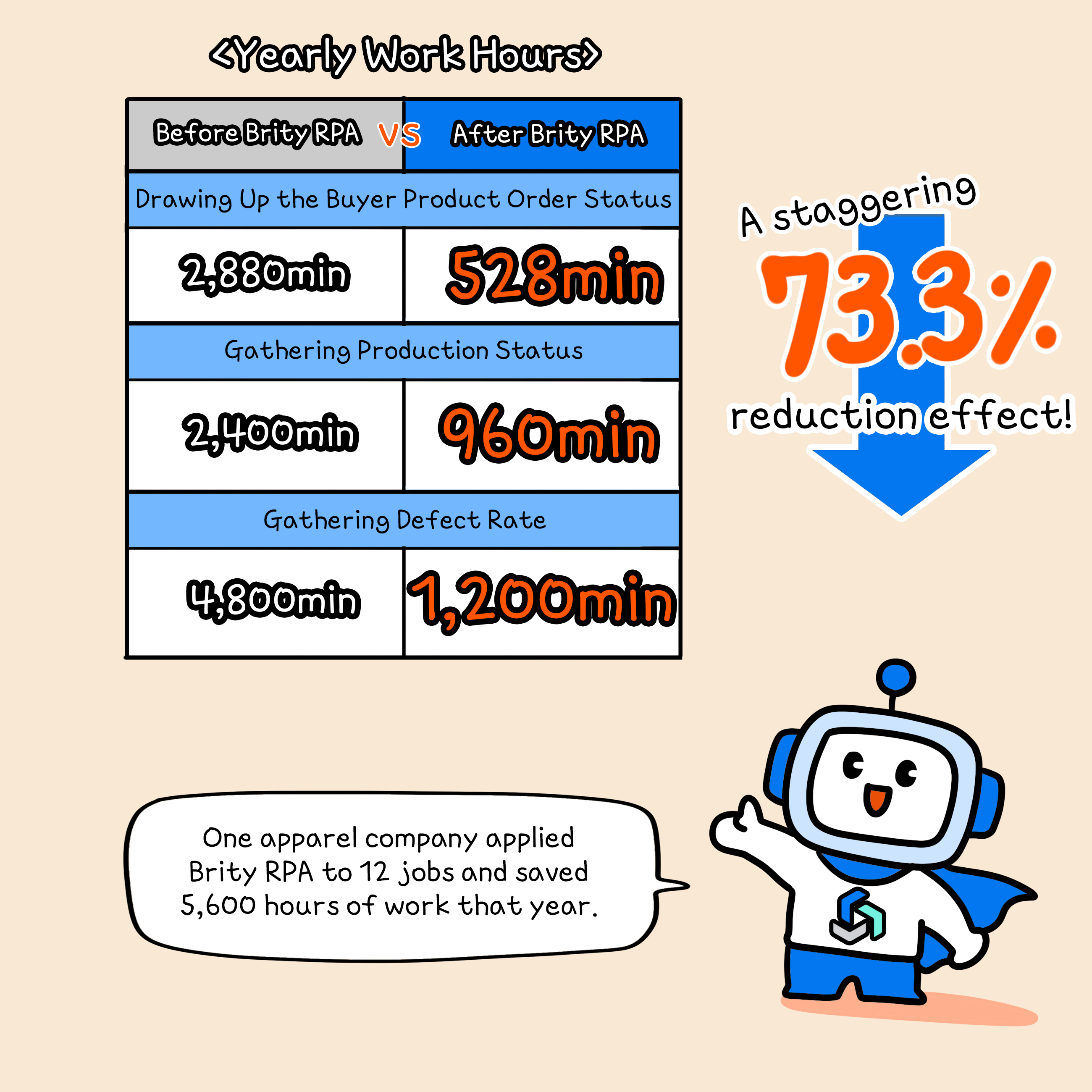

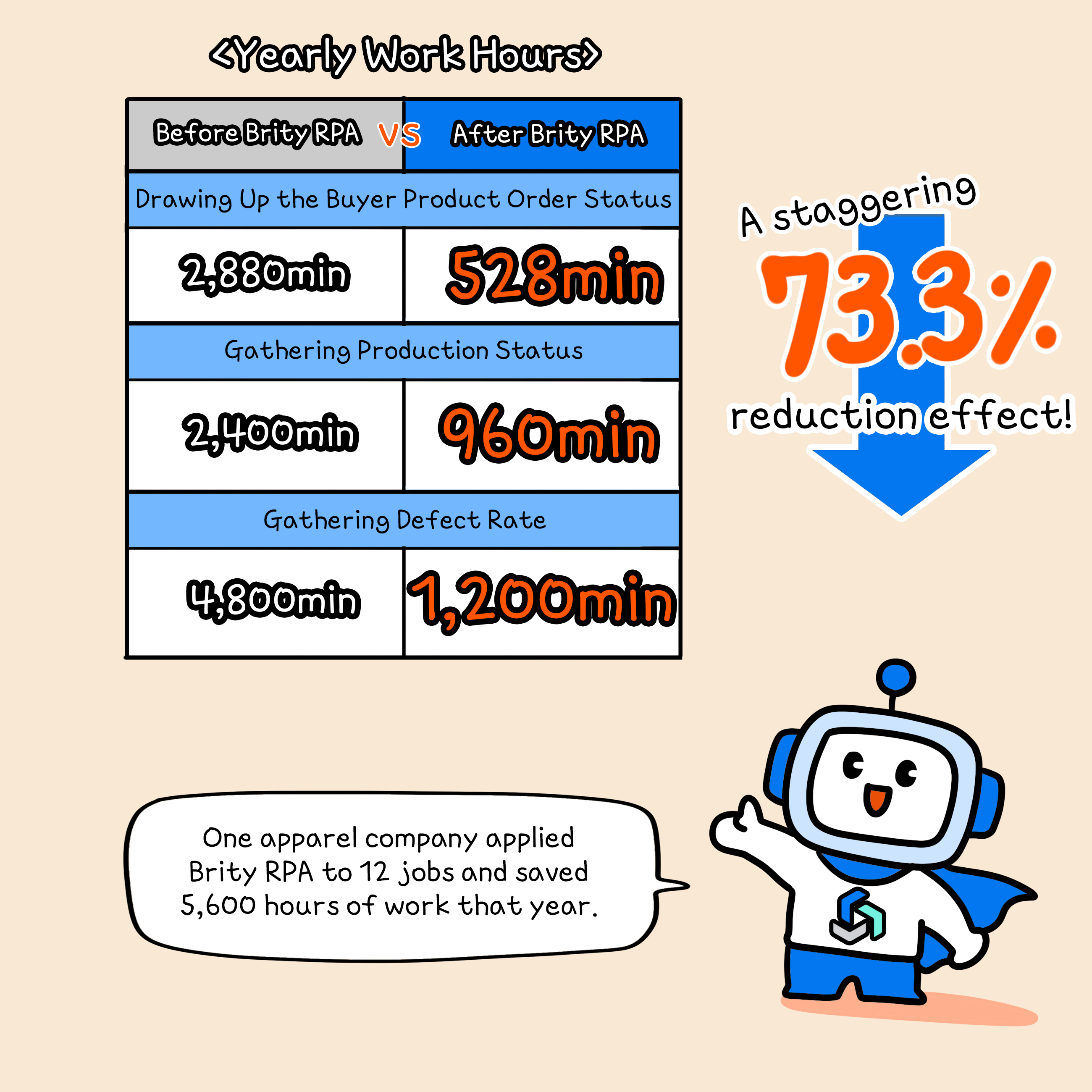

Yearly Working Hours(Before VS After Brity RPA)

- Drawing up the buyer product order status

Before Brity RPA: 2,800 min

After Brity RPA: 528 min

- Gathering production status

Before Brity RPA: 2,400 min

After Brity RPA: 960 min

- Gathering defect rates

Before Brity RPA: 4,800 min

After Brity RPA: 1,200 min

A staggering reduction effect! 73.3%

Brity Bot: One apparel company applied Brity RPA to 12 jobs and saved 5,600 hours of work that year.

Brity Bot: Have a smarter day in the manufacturing industry together with Brity RPA!

Ms. Deer: Now, I can just focus on making more good i-deer!

(Organized work) TA-----DA

This webcomics are also posted on Samsung SDS website and SNS pages including facebook and linkedin. You can share it with your customers to help them better understand Brity RPA.

+ Go to Facebook

+ Go to LinkedIn

About Kimong

Kimong is a webcomics creator who studied architecture in college but is now working full-time as an emoticon creator and Kakao Webtoon/Insta Toon writer who uses “dad jokes” as the main theme of his work. His key works include Kimong’s Life of a Pushover which recorded over 20 million views at Kakao Webtoon and his book Kimong Quits Job with Emoticon.