Digital SCM

AI Technology and Cloud-based Next-generation Supply Chain Optimization Service

Realize smarter, faster, and suppler next-generation SCM

Samsung SDS Digital SCM uses the next-generation technology, including native in-memory-based platform and ultra-high-speed planning engine, thoroughly prepares for uncertainty through scenario plan, and quickly reacts to the variability through the incremental plan.

Also, enhance the efficiency of decision-making by providing customized UI and differentiated mobile environment.

Differentiation

- Based on a flexible structure that can easily adopt new technology, you can immediately cope with the fast-changing environment.

-

Able to make a decision by a New Technology-based Scenario Plan

The management environment changes fast and so does the uncertainty. The management should make the best decision-making by building the potential scenarios simultaneously and evaluating the scenarios based on various management indicators, including profits and losses. Digital SCM enables a real-time scenario creation and quick alternatives building with a native in-memory platform and ultrahigh-speed plan building engine.

-

Quick Reaction to the Exception and Change of Supply Chain Through Incremental Plan

What core competitiveness SCM can offer in this hyper-connected global era is an immediate analysis of the impact of unexpected exceptions, such as emergency orders from the customer, supply plan change of the supplier, massive change on production and distribution progress, and capability to re-synchronize the supply chain without disrupting its overall plan. Samsung SDS Digital SCM immediately provides the efficiency analysis and resolution of the change using the incremental plan.

-

Support Digital Transformation of SCM Using New Technology, Including AI/ML, NLP, and RPA

Not only it provides the single-pane-of-glass visibility of the numerical data, which is required for SCM management, but also gives the qualitative information, including competitor and customer trends, to provide business intelligence that goes beyond the numbers. Support the demand analysis and forecast automation utilizing AI/ML and RPA and help to build the plan by providing the plan result analysis and problem-solving recommendation. Provide groundbreaking convenience with NLP-based conversational reporting, which can easily acquire the information without professional knowledge of the system.

-

SCM Innovation and Cutting TCO Cost Via SaaS Service

On-premise in-house development SCM system has been an obstacle to continuous SCM innovation due to its huge investment and operation cost. With Saas-type next-generation SCM solution, the company can perform the SCM innovation continuously in a favorable subscription system without worrying about the hardware/software cost and system upgrade. Next-generation SCM SaaS solution can realize the customized, unique process of the company based on best practices in the same industry.

Why SDS?

-

The Biggest SCM Specialists in Korea with Rich ExperienceSamsung SDS has Digital SCM team which is the largest in Korea, which includes around 80 people.

The Biggest SCM Specialists in Korea with Rich ExperienceSamsung SDS has Digital SCM team which is the largest in Korea, which includes around 80 people.

They finished 40 cases annually, 200 cases in total, and this is the largest number in Korea.

The Digital SCM team has worked with 50 different clients, including Samsung Electronics, Hankook Tire, and pharmaceuticals/shoe-making/food companies, and has been pleased to join their journey to success. -

A Total Care from Strategy to OperationThrough SCM innovation journey working over 20 years with Samsung affiliates, Samsung SDS provides a total service that enables SCM strategy, process innovation, system building, and system operation. They suggest a realistic innovation plan which reflects up-to-date technology and trend, apply to the real business, and enable sustainable operation. Only Samsung SDS can provide the service organically links the design, implementation, and operation.

A Total Care from Strategy to OperationThrough SCM innovation journey working over 20 years with Samsung affiliates, Samsung SDS provides a total service that enables SCM strategy, process innovation, system building, and system operation. They suggest a realistic innovation plan which reflects up-to-date technology and trend, apply to the real business, and enable sustainable operation. Only Samsung SDS can provide the service organically links the design, implementation, and operation. -

Customized Service For various Customer IndustryIt is important to provide the best of breed solution, which matches the customer’s industry and business.

Customized Service For various Customer IndustryIt is important to provide the best of breed solution, which matches the customer’s industry and business.

Samsung SDS Digital SCM provides the customized SCM that matches the customer’s needs and relies on the innovation know-how of Samsung group in different industries, including electronics, manufacturing, and service.

Case Studies

Global Electronics Manufacturer

We built the global sales and production plan management system over different product groups, including mobile and home appliances of manufacture and sales subsidiaries all over six continents. Since all employees all around the globe share the same information anywhere, any time, it is possible to have quick and transparent decision-making. Also, SCM operation efficiency has escalated by increasing the forecast accuracy using the new technology, including distribution data analysis and AI-based sales forecast, and preventing out-of-stock.

Pharmaceuticals

Pharmaceuticals needs to establish a manufacturing plan reflecting regulations for each country and customer. Also, it needs demand management considering the transparency of the distribution route and diversity of the distribution channel. Through SCM solution from Samsung SDS, establish the “Demand-Supply Consensus-based Plan System” which reflects the characteristics of pharmaceuticals and leads to the decrease of inventory cost and increase of operational efficiency.

Global OEM Shoemaking Manufacturer

A pair of shoes is manufactured through diverse processes, including cutting, sewing, manufacturing, and assembly of more than 100 raw materials. Considering the manufacturing characteristic that the synchronization of sewing component (uppers) and process component (soles) manufacture plan affects the productivity of the finished goods and industry characteristic of small quantity batch production, establish “All-Process Synchronization Manufacture Plan System” and improve the finished good manufacture rate.

Food Manufacturer

Considering the fact the sales promotion and inventory cost rise due to intensifying competition between companies, we introduced the Optimal Inventory calculation process for each base and implemented the data-based decision-making and operation system by building the post-supplement plan based on a system. We escalated the operation efficiency based on reduction of inventory/logistics cost and decrease of stock-out rate.

Service Offering

Provide a total service from SCM Strategy to Assessment, PI(Process Innovation), Implementation, and Operation.

Based on SCM assessment toolkit, which reflects the SCM innovation experience over 20 years, figure out SCM Value Leak Analysis. Comparing the operating level with the advanced cases, evaluate the process maturity and draw SCM innovation direction for improvement of business performance.

Design the innovation direction and To-Be process for the process of all SCM value chains over customer collaboration, demand and supply management, purchasing management, and supplier collaboration. Provide the process innovation strategy considering the overall up-to-date technology and industry trends and the technical deployability.

Not only does SCM system building need plan solution implementation, it also needs comprehensive services, such as integration of Legacy system (i.e. ERP), standard information management, and operation system establishment. Samsung SDS is the best partner and can provide the service for all areas as a system integrator with a rich experience of over 20 years.

Based on the SCM operation experience on Samsung affiliate, provide the optimal operation service regarding SaaS based SCM. Leave your worries about SCM system operation to Samsung SDS and focus on your business. Samsung SDS will provide the best-quality service.

Key Features

-

Comprehensive Demand Management

Support the system that manages the qualitative and quantitative data regarding the market, including sales information, customer trend, and competitors trends.

-

AI-Powered Forecasting

Based on AI, including machine learning and artificial intelligence model, consider the various factors affecting sales and support the Sell-Out and Sell-In demand forecast automation.

-

Most Advanced Planning Engine

Based on the experience of various industries, including high-tech, manufacturing, and food, use the API method for planning features and support so it can adapt flexibly.

-

Incremental Planning

Support to accurately analyze demand, supply, and raw material changes that directly affect the supply chain and immediately change the plan.

-

Scenario Based Planning

Able to establish a scenario plan for various policies and strategies by in-memory based plan and parallel plan, and support the comparative analysis between scenarios.

-

Planning Data Management

Analyze the performance data based on business automation and AI, draw the ideal standard value, and suggest the proper value.

-

Interactive Reporting

Provide real-time, NLP-based, ad-hoc report regarding the information the management wants to know, including sales.

-

Mobile SCM

Able to check and analyze the SCM-based management data, including sales/demand status, supply status, and profit and loss in a mobile environment.

-

Hyper Personalization

Provide KPI and business information that each role needs and increase the business efficiency by Context-based Guided Drilldown.

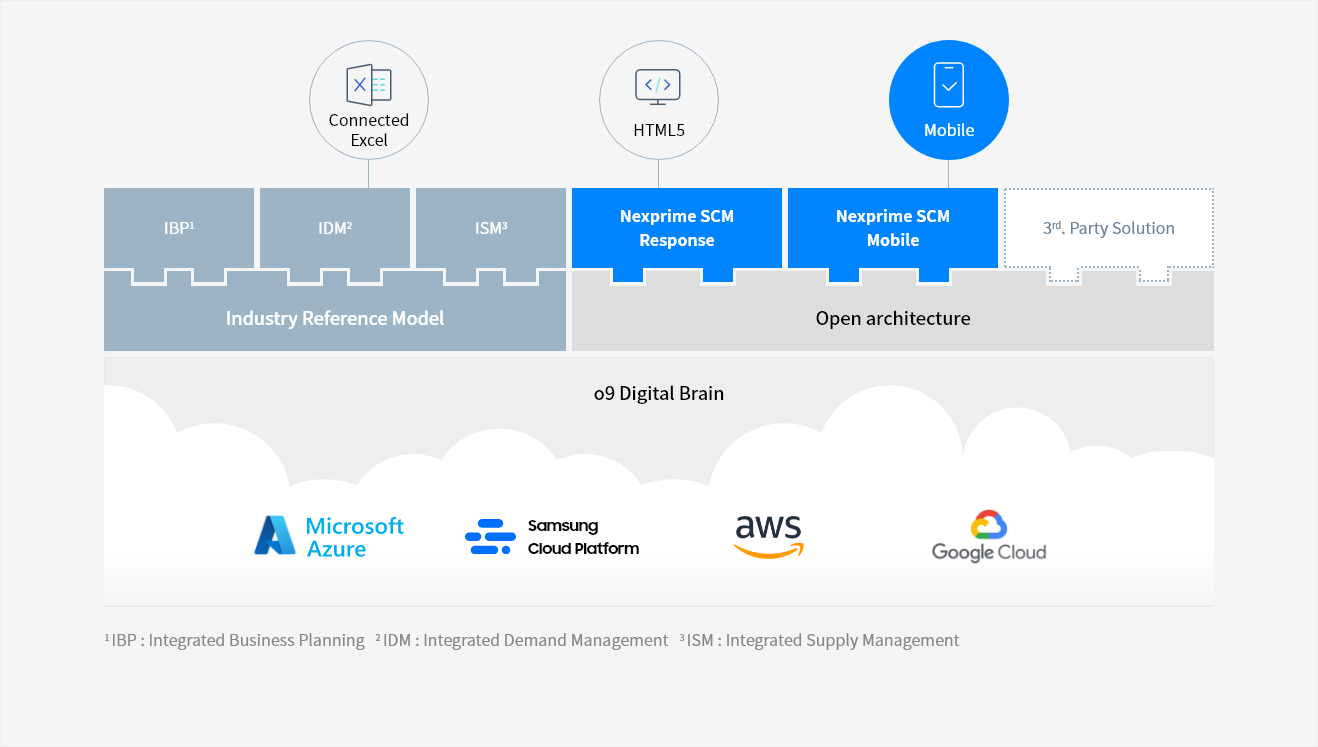

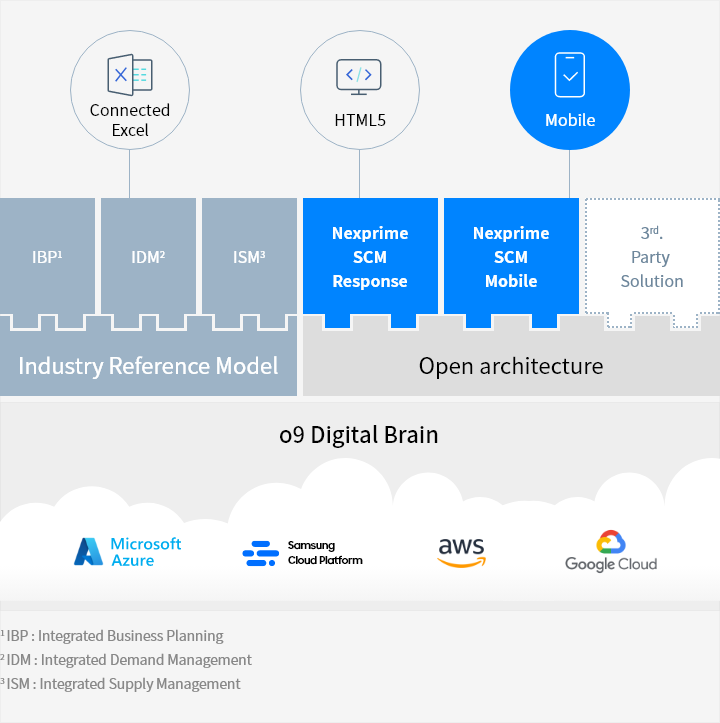

Nexprime SCM Architecture

- Planning System Tailored for Your Business

- Plug-In Architecture : AI/ML Forecast Model (R,Python, Nexprime SCM Response, Nexprime SCM Mobile, Nexprime SCM Sequencer, o9 SCS/LPS, Industrial FP Solvers

- Industry Reference Model by o9 & Samsung SDS

- o9 Digital Brain

- Any Clouds : Microsoft Azure, Amazon Web services, Google Cloud, SDS Cloud

Solutions

High-performance solver that creates optimal supply plan to meet the market demands

Mobile solution that provides business insights whenever, wherever you need

Videos

Innovate the supply chain with a smarter, faster, and suppler next-generation SCM platform.

Use Cases

-

Demand Forecast AutomationImprove the forecast accuracy and systemically manage the various demand forecast factors by eliminating the unnecessary manual job and person-in-charge dependency by AI-based demand forecast automation.

Demand Forecast AutomationImprove the forecast accuracy and systemically manage the various demand forecast factors by eliminating the unnecessary manual job and person-in-charge dependency by AI-based demand forecast automation. -

Scenario-based Decision-makingChange different plan strategy factors, including demand strategy, supply strategy, allocation strategy, and operation rules, and support the best decision-making by building and comparing the plans simultaneously for multiple scenarios to cope with the uncertainty.

Scenario-based Decision-makingChange different plan strategy factors, including demand strategy, supply strategy, allocation strategy, and operation rules, and support the best decision-making by building and comparing the plans simultaneously for multiple scenarios to cope with the uncertainty. -

Real-time Incremental Plan BuildingAnalyze the impact within the supply chain due to unexpected exceptions and changes using native in-memory platform-based plan engine in real time and re-synchronize the plan within the affected range. From this, we can react immediately to the change.

Real-time Incremental Plan BuildingAnalyze the impact within the supply chain due to unexpected exceptions and changes using native in-memory platform-based plan engine in real time and re-synchronize the plan within the affected range. From this, we can react immediately to the change. -

Mobile SCMProvide a Mobile SCM solution that can check the main information about SCM anywhere, any time, and collaborate.

Mobile SCMProvide a Mobile SCM solution that can check the main information about SCM anywhere, any time, and collaborate.

You can get business insight whenever, wherever with Mobile SCM optimized to mobile phones.

Related Offerings

Learn more about offerings, which support digital transformation

Lead the company's innovation and growth based on insights into business characteristics and experience by using the latest IT technologies

Learn moreDigital Core implementation for Intelligent Enterprise transformation

Learn more

Samsung SDS will be your digital transformation service specialist.